Product >> Rolling Stock Cable

FIREROL FRL-TW-05MP-SW-IOS

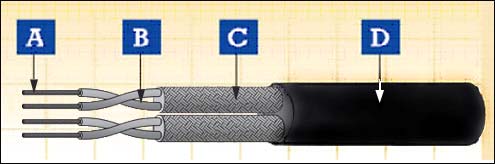

A.Conductor B.Insulation C.Screen D.Sheath

Application

-Used as power and control cable for protected installations inside and outside of rail and transport vehicles, where handling and installation cost are an important factor.

-Used in control, auxillary and main circuit wiring such as cable harnesses, switchboards and control panels, driver desks etc.

Construction

Conductor

Tinned annealed copper wires as defined in EN 50306-2

Insulation

LSZH special compound

Overall screen

Tinned annealed copper wires

Pair screen

Individual screened and sheathed. Screened according to EN 50306-3; Sheathed according to EN 50306-3 (S1. S2)

Pair Identification

Pairs numbered according to EN 50306-4

Outer sheath

LSZH special compound (S2. EM 101 - EM 104)

Electrical & Mechanical Properties

| Nominal Voltage | 300/500 V |

| Maximum Conductor Temperature | +90/+105 deg (fixed installation) |

| Minimum Permissible Ambient Temperature | -25/-40 deg (fixed installation) |

| Bending Radius | 10 x Overall Diameter |

Chemical & Environmental Properties

| EN 60684-2 | No fluorine |

| EN 50305; EN 60811-2-1 | Resistance to oil & fuel |

| EN 50305 | Resistance to ozone |

Fire Performance for rolling stock application

| EN 50306-2 | Hazard levels HL1, HL2/HL3, HL4 |

| DIN 5510-2 | Protection level 1/2/3/4 |

| BS 6853 | Interior use 1a, 1b, II; Exterior use 1a, 1b, II |

| NF F 16-101 | FO |

Fire Performance in general

| EN 50265-2-1; IEC 60332-1; BS 4066-1 | Vertical flame propogation for a single insulated wire or cable |

| EN 50266-2-4 + EN 50305; IEC 60332-3C; | Fire propagation of bunched wires and cables; |

| VDE 0472 Teil 804; BS 4066-3; NFC 32070 | |

| EN 50268-2; IEC 61034-2; VDE 0472 Teil 816 | Smoke density |

| EN 50267-2-1; IEC 60754-1; VDE 0472 Teil 815 | Halogen Free |

| EN 50267-2-2/3; IEC 60754-2; VDE 0472 Teil 813 | Corrosivity of gases (Acidity & Conductivity) |

| EN 50305; NFX 70-100; NFF 63808; TM1-04; BS6853 | Toxicity index |

| NFF 16101; NFF 63808; BS6853 | Smoke index |

FRL-TW-05MP-SW-IOS 300/500 V

NUMBER OF CORES AND NOMINAL CROSS SECTION |

MINIMUM THICKNESS OF SHEATH AT ANY POINT |

OVERALL DIAMETER |

WEIGHT |

|

(mm²) |

(mm) |

min. (mm) |

max. (mm) |

(kg/km) |

2 x 2 x 0.5 |

0.56 |

9.0 |

10.2 |

90 |

3 x 2 x 0.5 |

0.56 |

9.6 |

10.8 |

120 |

4 x 2 x 0.5 |

0.56 |

10.7 |

11.9 |

160 |

7 x 2 x 0.5 |

0.56 |

13.0 |

14.2 |

240 |

|

|

|

|

|

2 x 2 x 0.75 |

0.56 |

9.8 |

11.0 |

90 |

3 x 2 x 0.75 |

0.56 |

10.5 |

11.7 |

150 |

4 x 2 x 0.75 |

0.56 |

11.6 |

12.8 |

180 |

7 x 2 x 0.75 |

0.56 |

14.0 |

15.6 |

290 |

|

|

|

|

|

2 x 2 x 1.0 |

0.56 |

10.2 |

11.6 |

110 |

3 x 2 x 1.0 |

0.56 |

10.9 |

12.1 |

160 |

4 x 2 x 1.0 |

0.56 |

12.1 |

13.3 |

200 |

7 x 2 x 1.0 |

0.56 |

14.6 |

16.2 |

330 |

|

|

|

|

|

2 x 2 x 1.5 |

0.56 |

12.2 |

13.4 |

150 |

3 x 2 x 1.5 |

0.56 |

13.1 |

14.3 |

230 |

4 x 2 x 1.5 |

0.56 |

14.3 |

15.9 |

290 |

7 x 2 x 1.5 |

0.56 |

17.6 |

19.2 |

490 |